buckled surfaces

Independent design project

2011

carbon fiber cloth

aluminum sheet

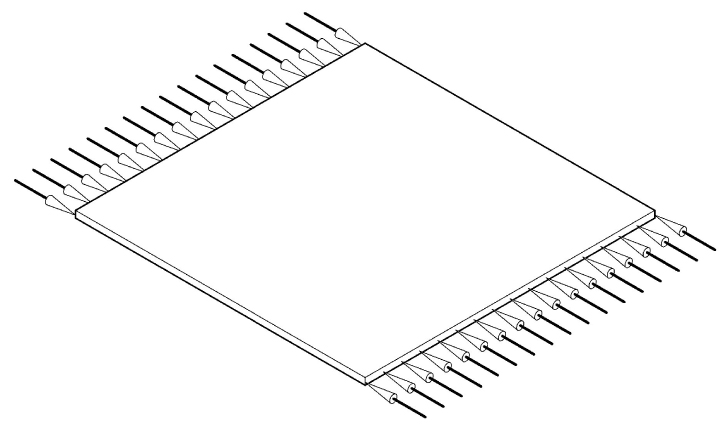

steel tubing

Rhino3d

CadrePro

(Scroll down for image gallery)

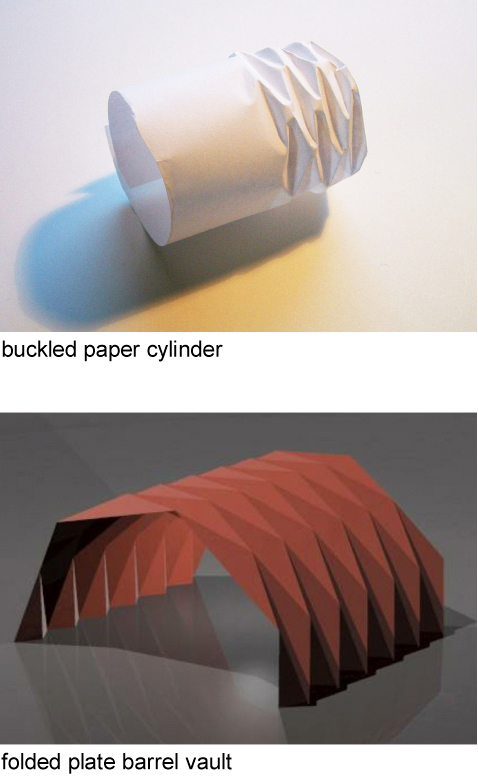

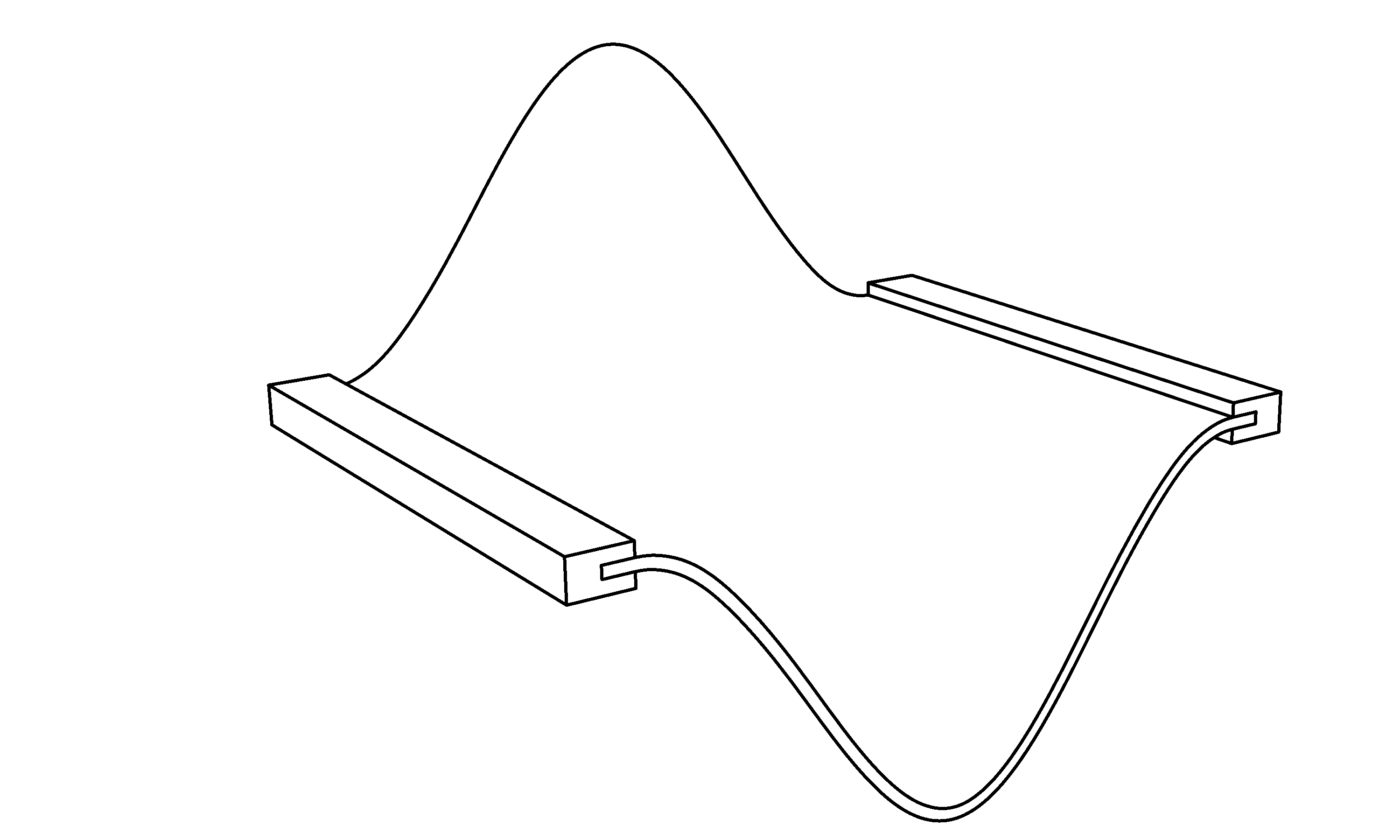

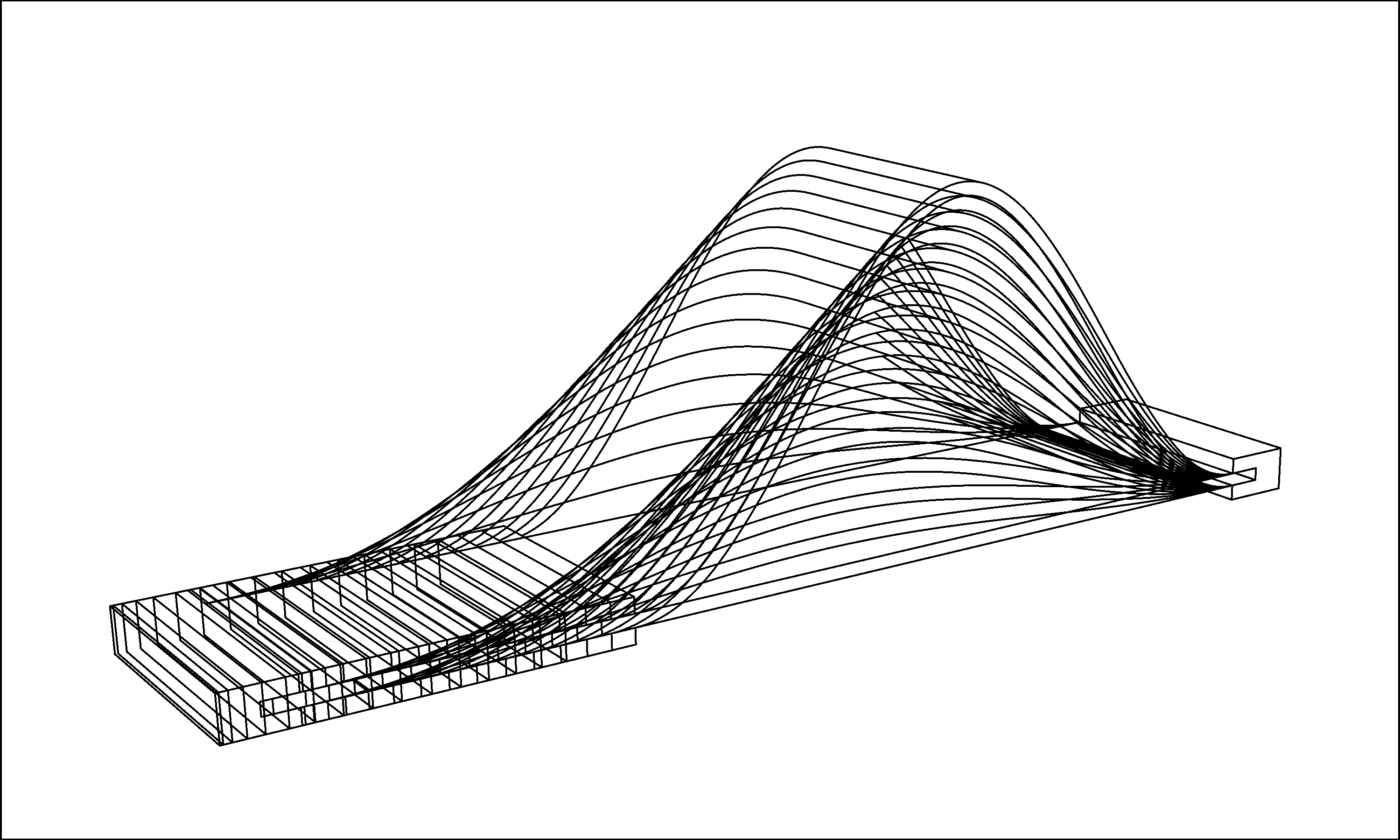

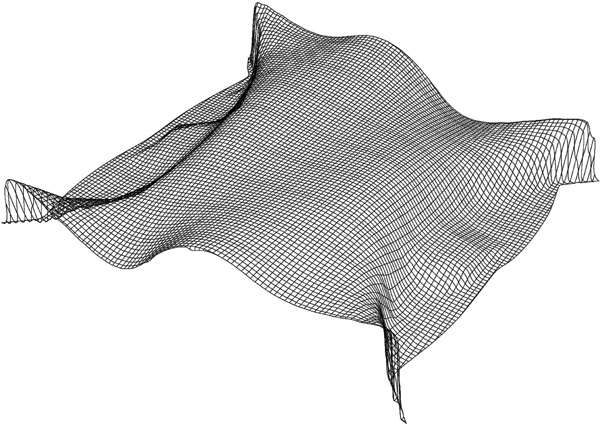

This project was a form-finding exercise arising from an observation that a buckled tube creases into a folded-plate barrel vault arrangement, and that a buckled strut approximates an arch. The resulting question: can buckling force generate a form that is structural when loaded in a perpendicular direction to the original force? However, buckling behavior is inherently unpredictable and defies computational simulation.

A technique was devised to use Finite Element Method structural analysis to simulate buckling behavior, and to generate forms. As this behavior is unpredictable, each successful analysis would produce differing results, and more often produced a software crash.

Following these computational experiments, a mechanical device was constructed to produce direct results in a material. Sheets of .070” thick x 36” long aluminum were slowly buckled to witness the propagation of deformations.