CAPPA spaceFRAMES

(PROJECT WITH STUDENTS)

Course: Advanced Design Studio

University of Texas at Arlington

Spring, 2019

16 gauge cold rolled steel sheet

Dimensional lumber

Rhino3D

Grasshopper

RhinoCAM

(Scroll down for image gallery)

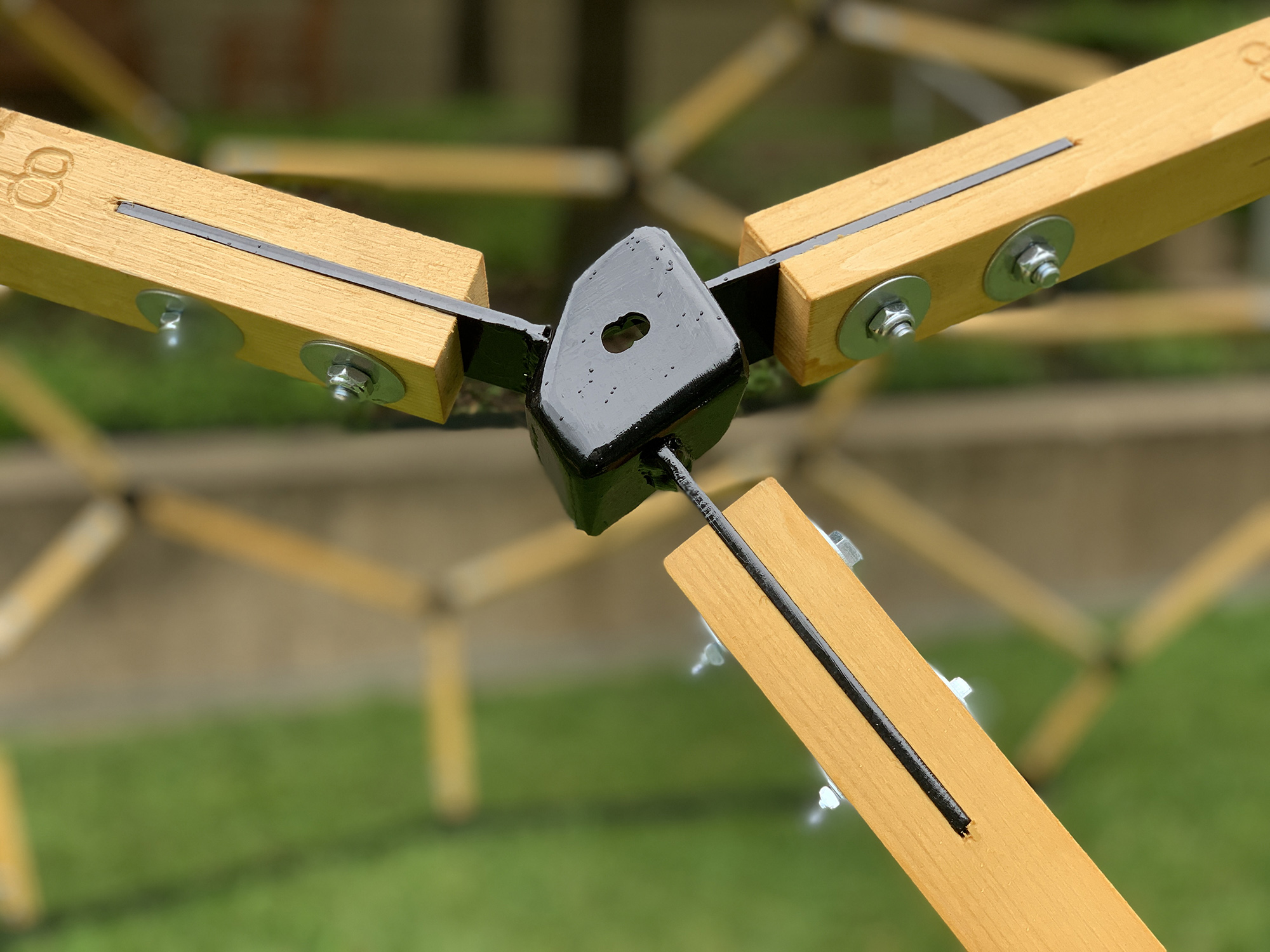

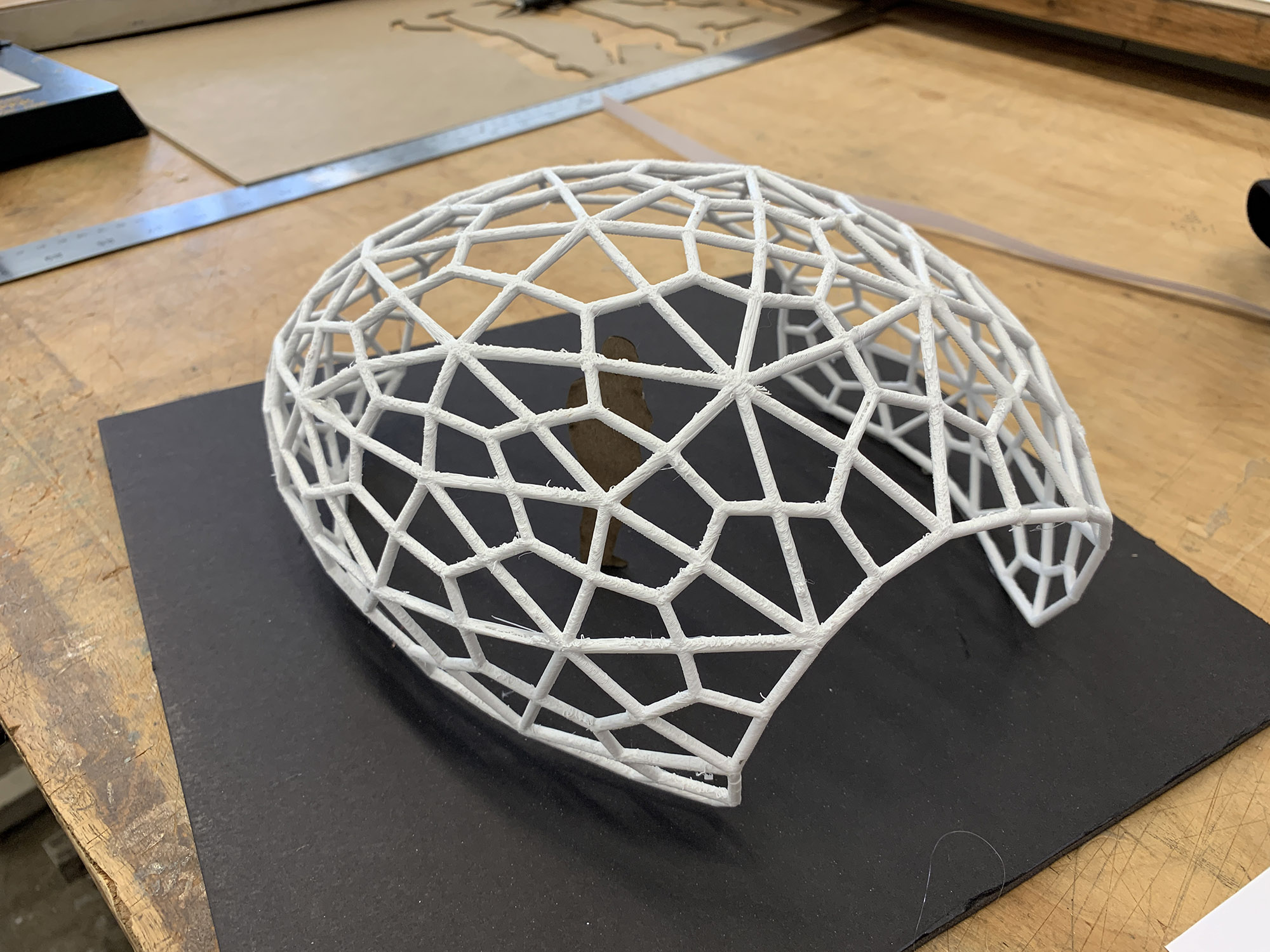

This structure was designed using a computational form-finding method, as a class project for a course that I taught that focused on shell structures, and the use of digital fabrication equipment to manufacture large numbers of unique components.

The first phase of this course concentrated on developing an overall surface form, using a range of digital form-finding techniques. From this form, multiple methods of subdividing the surface into straight line segments and intersecting point nodes were studied. A subdivision strategy that results in three struts coming into each node was chosen. As each of these 88 nodes is unique, a parametric design and fabrication system needed to be developed which could allow for the mass customization of these components. Not only does the included angle between wooden struts vary, but their axial rotation also differs as each strut enters a node. A series of prototype joints were constructed, to refine both the design and fabrication process. Fabrication of the wood struts and welded steel nodes took approximately two weeks, and the final assembly of the structure took less than two hours.